Use of Paving Sealers

Once you have had your driveway or patio professionally cleaned by us, it is worthwhile considering having the cleaned area treated with a sealant. The reasons for choosing to have the paved areas sealed are summarised as follows:

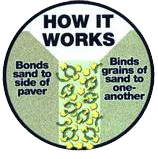

- Strengthens & maintains paving performance, as the sand is bonded by the sealant.

- Reduces surface porosity thereby resisting the penetration of stains

- Inhibits the growth of weeds, grass, algae & lichen.

- Helps to prevent the colonisation of ants nests

- Renders the area easier to maintain in the future.

- Enhances the appearance, especially older paving blocks.

We are able to offer customers a choice of different types of sealant; these are either a basic matt acrylic finish, or a more durable pre-polymer urethane sealant, in either matt, or gloss form.

A comparison of block paving before and after sealing is shown in the picture opposite. There are a variety of sealants available and we will recommend the most suitable, which is chosen on the basis of economy and the wear characteristics needed in the expected use of the surface being treated.

The examples which follow show typical applications of the sealants we have used to satisfy customers requirements.

1. Acrylic sealants

The acrylic sealant shown in the picture to the left is the low cost option and is a two-coat process using a solution of an acrylic polymer in xylene. The polymer solution soaks into the jointing sand and the blocks, then after solvent evaporation it is left firmly bonded and coated. This has a stabilising effect on the driveway, preventing loss of the actual jointing sand and inhibiting the growth of weeds and grass in the joints. This sealing process also helps to prevent the colonisation of ant nests. The matt-look finish given to the surface enhances the appearance of the of the driveway considerably and has a life expectancy of 1 to 3 years dependent on local conditions.

The acrylic sealant shown in the picture to the left is the low cost option and is a two-coat process using a solution of an acrylic polymer in xylene. The polymer solution soaks into the jointing sand and the blocks, then after solvent evaporation it is left firmly bonded and coated. This has a stabilising effect on the driveway, preventing loss of the actual jointing sand and inhibiting the growth of weeds and grass in the joints. This sealing process also helps to prevent the colonisation of ant nests. The matt-look finish given to the surface enhances the appearance of the of the driveway considerably and has a life expectancy of 1 to 3 years dependent on local conditions.

2. Pre-polymer urethane sealants Gloss or Matt

.jpg)

The more expensive pre-polymer urethane sealants perform a similar function to the acrylic option, but they are more durable and last typically twice as long between full treatments. As with the acrylic coating process the pre-polymer urethane soaks into the jointing sand, to bind the particles and sides of the blocks, or paving stones together. Then after this penetration actual polymerisation of the urethane takes place in-situ as a result of solvent evaporation, atmospheric and residual moisture. The urethane plastic is therefore effectively cured in place producing a very strong stable bond, which retains the normal flexural properties of the pavement. Once sealed with the urethane treatment, the coated driveway will withstand washing with a normal jet washer.

The gloss version of the urethane polymer known as gloss Resiblock Superior is a two-coat process and is therefore more expensive since it uses more material. The properties are similar, except that the surface of the blo.jpg) cks remains coated and are normally somewhat darker than the original colour. The two-coat process means that it can only be applied in a period of good weather to ensure a consistent finish. The picture shown above is a driveway that has been sealed with the gloss pre-polymer urethane sealant. This shows how effectively the sealant enhances the surface of the driveway. In addition to the gloss version of Resiblock Superior , there is also a matt Resiblock Superior option, shown in the image opposite which is also a two-coat process. The surface coating remains on the surface of the blocks unlike the matt Resiblock-22 sealant. The price for the matt Resiblock Superior is the same as the gloss version and is chosen by those customers who like the blocks coated, but with a matt appearance.

cks remains coated and are normally somewhat darker than the original colour. The two-coat process means that it can only be applied in a period of good weather to ensure a consistent finish. The picture shown above is a driveway that has been sealed with the gloss pre-polymer urethane sealant. This shows how effectively the sealant enhances the surface of the driveway. In addition to the gloss version of Resiblock Superior , there is also a matt Resiblock Superior option, shown in the image opposite which is also a two-coat process. The surface coating remains on the surface of the blocks unlike the matt Resiblock-22 sealant. The price for the matt Resiblock Superior is the same as the gloss version and is chosen by those customers who like the blocks coated, but with a matt appearance.

3. Resiblock 22

%20-%20Copy%20-%20Copy.jpg)

The matt Resiblock 22 product is a single coat application sealant and an example is shown in the picture to the right. This sealant bonds the jointing sand strongly and seals the overall surface. After some time the surface coating is lost returning the paving blocks to their original colour. The block paving is nevertheless sealed, because the blocks have been impregnated and the sand is bonded